Canadian Winters can be brutal on hydraulic and lubrication systems. As the temperature drops, all sorts of new noises come out of these systems. One of which is a high pitch sound that usually gets associated with the effect of cavitation, but can also be caused by aeration. Both will produce a very similar sound and usually causes head scratching confusion to technicians and designers alike.

So what’s the difference?

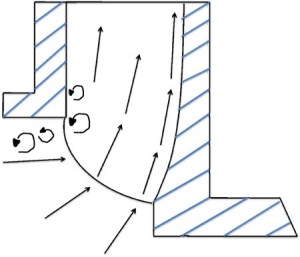

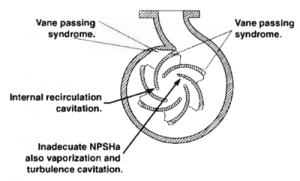

Cavitation happens when the pump is starved of fluid. Basically let’s say the pump requires 10 GPM but can only get 8 GPM then there is a volume equal to 2 GPM of nothing. Some call it air bubbles, but in fact it’s a vacuum space. As those vacuum bubbles transfer from the inlet side of the pump to the outlet side, they go from a high vacuum state to a high pressure state. This causes the vacuum bubbles to implode. The implosion creates a shock wave and emits a high pitch sound. You can notice that the higher the outlets pressure the louder the sound, indicating a stronger shock wave, causing damage to the pump.

When troubleshooting, a vacuum gauge must be installed on the inlet line as close to the pump as possible. Cavitation will be indicated by a high vacuum reading on the gauge. The maximum safe pump inlet vacuum depends on the type of pump.

Cavitation can be caused by several things including suction strainers, undersized inlet lines, long inlet lines, clogged air breather, using pressure hose instead of proper vacuum rated hose, high viscosity fluid and many more.

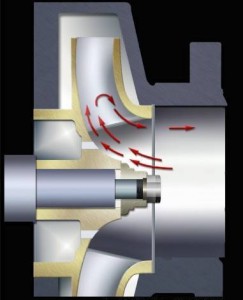

Aeration happens when air enters the system. As the air bubbles transfer from the inlet side of the pump to the outlet, they are compressed, causing very high localised heat. Since these air bubbles are surrounded by a hydrocarbon fluid, it has the same effect as a diesel engine. This is called micro dieseling. This effect causes a very similar sound to cavitation. Contrary to cavitation the vacuum gauge will read little to no vacuum.

Aeration can be caused by several things including no return line down tube in the reservoir, mixing different oils, undersized return lines, loose inlet hose or fitting, low reservoir volume, high viscosity fluid and others as well.

Both aeration and cavitation cause pump damage, fluid degradation, contamination and heat resulting in a negative effect on the overall efficiency and life expectancy of the system.