Hydraulic Motors

Posted by MobileHydraulictips.com+ on Tuesday, September 24, 2013

Advertisement:

Hydraulic motors are rotary actuators that convert hydraulic, or fluid energy into mechanical power. They work in tandem with a hydraulic pump, which converts mechanical power into fluid, or hydraulic power. Hydraulic motors provide the force and supply the motion to move an external load.

Three common types of hydraulic motors are used most often today—gear, vane and piston motors—with a variety of styles available among them. In addition, several other varieties exist that are less commonly used, including gerotor or gerolor (orbital or roller star) motors.

Hydraulic motors can be either fixed- or variable-displacement, and operate either bi-directionally or uni-directionally. Fixed-displacement motors drive a load at a constant speed while a constant input flow is provided. Variable-displacement motors can offer varying flow rates by changing the displacement. Fixed-displacement motors provide constant torque; variable-displacement designs provide variable torque and speed.

Torque, or the turning and twisting effort of the force of the motor, is expressed in in.-lb or ft-lb (Nm). Three different types of torque exist. Breakaway torque is normally used to define the minimum torque required to start a motor with no load. This torque is based on the internal friction in the motor and describes the initial “breakaway” force required to start the motor. Running torque produces enough torque to keep the motor or motor and load running. Starting torque is the minimum torque required to start a motor under load and is a combination of energy required to overcome the force of the load and internal motor friction. The ratio of actual torque to theoretical torque gives you the mechanical efficiency of a hydraulic motor.

Defining a hydraulic motor’s internal volume is done simply by looking at its displacement, thus the oil volume that is introduced into the motor during one output shaft revolution, in either in.3/rev or cc/rev, is the motor’s volume. This can be calculated by adding the volumes of the motor chambers or by rotating the motor’s shaft one turn and collecting the oil manually, then measuring it.

Flow rate is the oil volume that is introduced into the motor per unit of time for a constant output speed, in gallons per minute (gpm) or liter per minute (lpm). This can be calculated by multiplying the motor displacement with the running speed, or simply by gauging with a flowmeter. You can also manually measure by rotating the motor’s shaft one turn and collecting the fluid manually.

Three common designs Keep in mind that the three different types of motors have different characteristics. Gear motors work best at medium pressures and flows, and are usually the lowest cost. Vane motors, on the other hand, offer medium pressure ratings and high flows, with a mid-range cost. At the most expensive end, piston motors offer the highest flow, pressure and efficiency ratings.

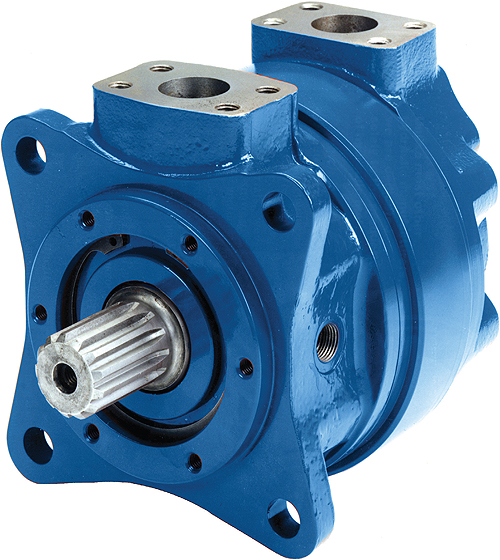

External gear motor.

Gear motors feature two gears, one being the driven gear—which is attached to the output shaft—and the idler gear. Their function is simple: High-pressure oil is ported into one side of the gears, where it flows around the gears and housing, to the outlet port and compressed out of the motor. Meshing of the gears is a bi-product of high-pressure inlet flow acting on the gear teeth. What actually prevents fluid from leaking from the low pressure (outlet) side to high pressure (inlet) side is the pressure differential. With gear motors, you must be concerned with leakage from the inlet to outlet, which reduces motor efficiency and creates heat as well.

In addition to their low cost, gear motors do not fail as quickly or as easily as other styles, because the gears wear down the housing and bushings before a catastrophic failure can occur.

At the medium-pressure and cost range, vane motors feature a housing with an eccentric bore. Vanes rotor slide in and out, run by the eccentric bore. The movement of the pressurized fluid causes an unbalanced force, which in turn forces the rotor to turn in one direction.

Vane motor

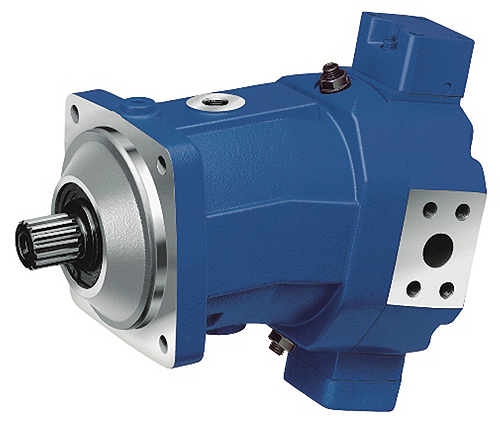

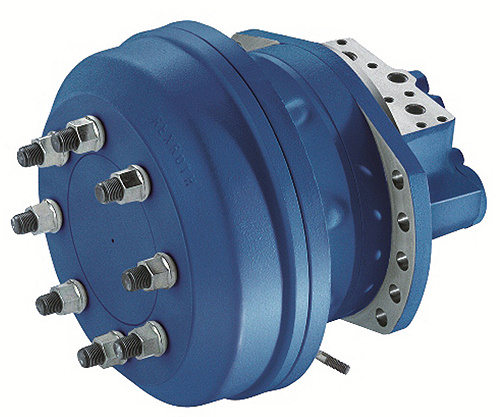

Piston-type motors are available in a variety of different styles, including radial-, axial-, and other less common designs. Radial-piston motors feature pistons arranged perpendicularly to the crankshaft’s axis. As the crankshaft rotates, the pistons are moved linearly by the fluid pressure. Axial-piston designs feature a number of pistons arranged in a circular pattern inside a housing (cylinder block, rotor, or barrel). This housing rotates about its axis by a shaft that is aligned with the pumping pistons. Two designs of axial piston motors exist—swashplate and bent axis types. Swashplate designs feature the pistons and drive shaft in a parallel arrangement. In the bent axis version, the pistons are arranged at an angle to the main drive shaft.

Variable, axial piston motor, with the bent-axis design.

Of the lesser used two designs, roller star motors offer lower friction, higher mechanical efficiency and higher start-up torque than gerotor designs. In addition, they provide smooth, low-speed operation and offer longer life with less wear on the rollers. Gerotors provide continuous fluid-tight sealing throughout their smooth operation.

Radial piston motor.

Specifying hydraulic motors

There are several important things to consider when selecting a hydraulic motor.

You must know the maximum operating pressure, speed, and torque the motor will need to accommodate. Knowing its displacement and flow requirements within a system is equally important.

Hydraulic motors can use different types of fluids, so you must know the system’s requirements—does it need a bio-based, environmentally-friendly fluid or fire resistant one, for example. In addition, contamination can be a problem, so knowing its resistance levels is important.

Cost is clearly a huge factor in any component selection, but initial cost and expected life are just one part of this. You must also know the motor’s efficiency rating, as this will factor in whether it runs cost-effectively or not. In addition, a component that is easy to repair and maintain or is easily changed out with other brands will reduce overall system costs in the end. Finally, consider the motor’s size and weight, as this will impact the size and weight of the system or machine with which it is being used.